Here Is A Quick Way To Solve A Tips About What Voltage Can FR4 Withstand

FR4 and Voltage

1. Understanding the Basics of FR4

So, you're wondering about FR4 and how much voltage it can handle? It's a fair question, especially if you're tinkering with electronics, designing circuit boards, or just generally curious about the materials around you. FR4, short for Flame Retardant 4, is a common material used in printed circuit boards (PCBs). Think of it as the unsung hero holding all those fancy electronic components together.

Its essentially a composite material made of woven fiberglass cloth with an epoxy resin binder. This combination gives it strength, rigidity, and, importantly, decent electrical insulation properties. But "decent" isn't a number, is it? Let's delve a little deeper. What are we really talking about when we ask what voltage FR4 can withstand?

Well, it boils down to dielectric strength. This is the maximum electric field that a material can withstand before it breaks down and starts conducting electricity. In simpler terms, it's the point where the insulation gives up and lets the electricity flow right through, which is generally not what you want happening in your electronics.

And here's a little secret: FR4 isn't created equal. There are different grades and thicknesses, and these variations significantly impact its voltage withstanding capabilities. Just imagine the difference between a flimsy piece of paper and a thick, sturdy cardboard box. Same principle applies here!

The Numbers Game

2. Diving into the Specs

Alright, let's get down to the numbers, shall we? Brace yourself, because it involves a bit of geek-speak. The dielectric strength of FR4 is typically measured in volts per mil (V/mil), where a "mil" is one-thousandth of an inch. A typical value for FR4 is around 800 to 1200 V/mil. That sounds like a lot, right? Well, it depends on the thickness of the FR4.

For instance, a common FR4 thickness used in PCBs is around 0.062 inches (or 62 mils). If we take a dielectric strength of, say, 1000 V/mil, you might think it can handle a whopping 62,000 volts! Hold your horses! Thats theoretical maximum under ideal lab conditions. In the real world, things get a little more complicated.

Think of it like this: a car might have a speedometer that goes up to 150 mph, but you probably wouldn't drive it that fast on a regular road. Similarly, you wouldn't want to push FR4 to its absolute limit in a practical application. Safety margins are key!

Factors like temperature, humidity, the quality of the FR4 material itself, and even the presence of contaminants can all affect its breakdown voltage. So, while the datasheet might say 1000 V/mil, you'll want to design your circuits with a significant buffer to ensure reliable and safe operation.

Fr4 Dielectric Constant And PCB Board

Real-World Considerations

3. Factors Influencing Voltage Withstand

Okay, so we know about dielectric strength, but what else can mess with FR4s ability to hold voltage? Temperature, for starters, plays a big role. As FR4 heats up, its insulation properties tend to decrease. Its like when you get tired; youre just not as effective as you were when you were fresh.

Humidity is another sneaky culprit. Moisture can get absorbed into the FR4 material, especially if its not properly sealed or coated. This moisture can create conductive paths, weakening the insulation and making it easier for voltage to break through. Imagine trying to build a sandcastle with wet sand versus dry sand — same principle applies!

Manufacturing quality is paramount. Imperfections in the FR4, such as voids or delaminations (where the layers separate), can create weak spots that are more susceptible to voltage breakdown. This is why its so important to source your FR4 from reputable suppliers who maintain strict quality control.

And lets not forget about surface contamination. Dust, dirt, and other particles on the FR4 surface can act as conductive pathways, reducing the effective insulation. Keeping your PCBs clean is essential for long-term reliability.

Practical Applications and Safety Margins

4. Designing for Reliability

Alright, let's talk about how this all applies in the real world. When designing circuits, its crucial to incorporate adequate safety margins to account for all the factors weve discussed. A good rule of thumb is to aim for a voltage rating thats significantly higher than the maximum voltage your circuit will actually experience.

For example, if youre working with a 12V circuit, you might want to choose FR4 with a dielectric strength that can comfortably handle several hundred volts, or even thousands, depending on the criticality of the application. Its better to be safe than sorry, especially when dealing with electricity.

Consider the environment where your circuit will be operating. If its going to be in a hot, humid environment, youll need to be even more conservative with your voltage ratings. Think of it like dressing for the weather; you wouldnt wear a t-shirt in the snow, would you?

And dont forget about testing! Prototype testing is essential to verify that your circuit is performing as expected and that the FR4 is holding up under real-world conditions. This can involve subjecting your circuit to high-voltage stress tests to identify any potential weaknesses.

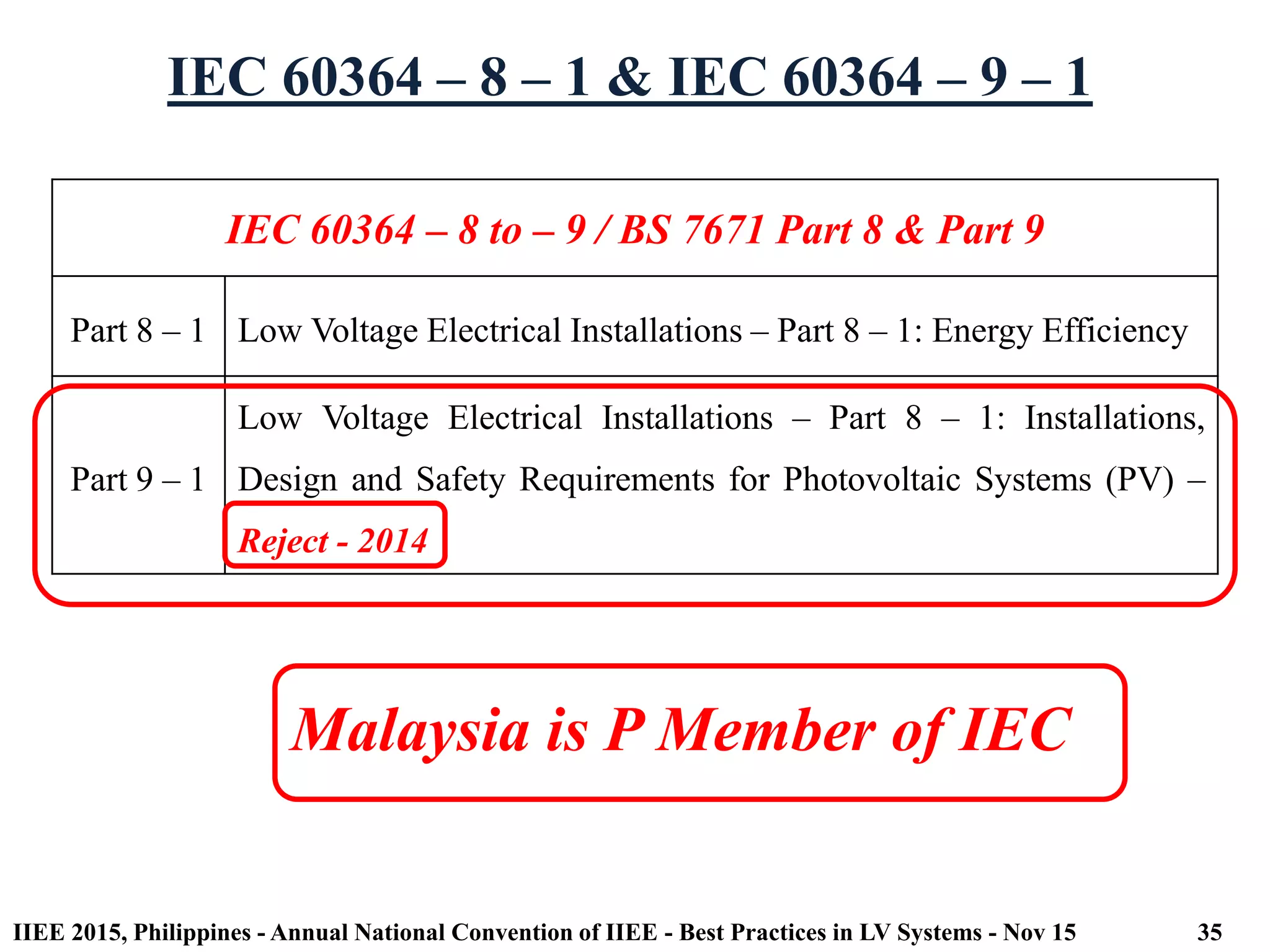

Fr4 Best Practicesinlowvoltagesystems PPT

Beyond FR4

5. Exploring Other PCB Materials

While FR4 is the workhorse of the PCB world, it's not the only option out there. For applications that require even higher voltage withstanding capabilities, or other specialized properties, there are alternative materials to consider. Think of it like choosing the right tool for the job; a hammer is great for nails, but not so great for screws.

Materials like polyimide and Teflon offer superior electrical insulation and thermal performance compared to FR4. Polyimide, for instance, can withstand higher temperatures and voltages, making it suitable for demanding applications like aerospace and automotive electronics. Teflon boasts excellent dielectric properties and is often used in high-frequency circuits.

However, these alternative materials typically come with a higher price tag than FR4. So, its important to weigh the cost-benefit ratio when making your material selection. Is the extra performance worth the added expense?

Ultimately, the best choice of PCB material depends on the specific requirements of your application. Consider factors like voltage levels, operating temperature, frequency, and budget to make an informed decision. And when in doubt, consult with a PCB manufacturer or engineer for expert guidance.