Cool Tips About Which Is Better 2205 Or 316 Stainless Steel

2205 vs. 316 Stainless Steel

1. Understanding Your Metal Options

Okay, so you're staring down the barrel of a metal selection decision, and the choices seem endless. You've probably heard whispers of "2205" and "316 stainless steel," maybe even with someone throwing around terms like "duplex" and "austenitic." Don't sweat it! We're going to break down what makes each of these metals tick, and more importantly, help you figure out which one best suits your needs. Think of it as a metal matchmaking service, but less romantic, and way more practical.

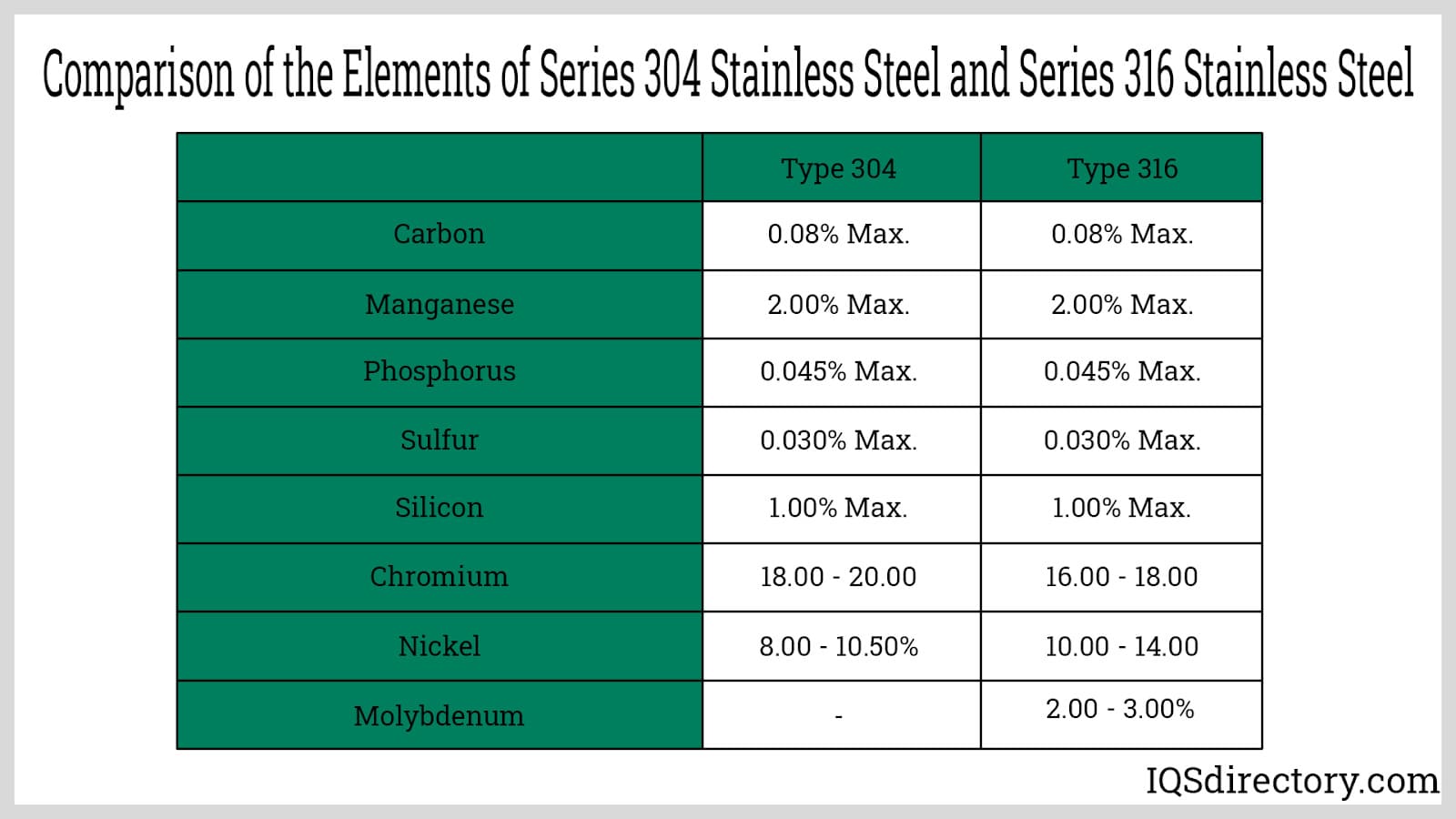

Stainless steel, in general, is your go-to for corrosion resistance. That's its superpower. But not all stainless steels are created equal. They differ in composition, which directly impacts their strength, weldability, and how well they hold up against different environments. The key ingredients are chromium and nickel, but the specific amounts of each, plus the addition of other elements like molybdenum and nitrogen, make all the difference. It's like baking a cake; same basic ingredients, wildly different outcomes depending on the recipe!

So, before we dive into the nitty-gritty (okay, I almost said it!), let's establish that choosing the right metal can save you headaches and money down the line. Whether you're building a boat, constructing a chemical processing plant, or just need some robust hardware for your backyard project, getting it right matters. Imagine using the wrong metal and having your project rust away before your eyes! Not a pretty picture, right?

Well avoid those metal-mageddon scenarios. We will dive in and help you choose the right kind of metal to use for your projects.

Stainless Steel 316 What Is It? How It Made? Grades

The 316 Stainless Steel Story

2. What Makes 316 Tick?

316 stainless steel is like that dependable friend who's always there for you. It's an austenitic stainless steel, meaning it has a high chromium and nickel content, along with molybdenum. Molybdenum is the secret sauce that gives 316 enhanced corrosion resistance, especially against chlorides (think salt water). That's why it's a popular choice in marine environments, chemical processing, and food processing industries.

Think of 316 as the all-around player on your metal team. Its got good strength, excellent weldability, and its relatively easy to fabricate. You'll find it used in everything from surgical instruments to kitchen sinks. Its a tried-and-true material that's been around for a while and has a solid reputation for reliability. It's not flashy, but it gets the job done, and done well. You are probably even using it right now!

However, it's not invincible. Under extremely corrosive conditions, or at high temperatures, 316 can still be susceptible to pitting and crevice corrosion. And while it's stronger than some other stainless steels, it's not the strongest metal on the block. If you need something with serious muscle, you might want to consider other options. So, imagine it as a solid foundation, but not necessarily the whole building.

Its versatility also comes from its formability. It can be easily bent and shaped to suit various applications. Because of its strength and corrosion resistance, 316 stainless steel is used in many environments and situations where these characteristics are important.

2205 Duplex Stainless Steel

3. Understanding the Power of Duplex

Now, let's talk about 2205 stainless steel. This is where things get a little more interesting. 2205 is a "duplex" stainless steel, meaning it has a mixed microstructure of austenite and ferrite. This combination gives it a unique blend of properties. Think of it as a hybrid car it gets the best of both worlds. Its the best of two different kinds of stainless steel.

What are those "best of both worlds" properties? Well, 2205 boasts significantly higher strength than 316. We're talking almost twice the yield strength! It also offers improved resistance to pitting, crevice corrosion, and stress corrosion cracking. Basically, it's tougher, more durable, and better equipped to handle harsh environments. It is strong and durable and not afraid to show it!

The downside? 2205 can be a bit more challenging to weld and fabricate than 316. It requires more precise control of welding parameters to avoid issues like embrittlement. And because it's a bit more specialized, it's typically more expensive than 316. You're paying for the extra performance, after all. So, while it's a powerhouse, it requires a bit more finesse and a bigger investment.

Imagine it this way: 316 is like a reliable sedan, while 2205 is like a powerful pickup truck. Both can get you where you need to go, but one is better suited for hauling heavy loads and tackling rough terrain. The pickup is more powerful but also requires a bit more skill to drive, whereas the sedan is just easy for everyone.

Head-to-Head

4. Strength, Corrosion Resistance, and Cost

Alright, let's get down to brass tacks. Here's a side-by-side comparison of 2205 and 316 in the areas that matter most:

Strength: 2205 wins this category hands down. Its higher yield strength means it can withstand greater loads and stresses without deforming. If your application requires high strength, 2205 is the clear choice.

Corrosion Resistance: Both 2205 and 316 offer excellent corrosion resistance. However, 2205 generally performs better in chloride-rich environments and is more resistant to pitting, crevice corrosion, and stress corrosion cracking. So, if you're dealing with harsh chemicals or marine environments, 2205 has the edge.

Weldability and Fabricability: 316 is generally easier to weld and fabricate than 2205. 2205 requires more precise control of welding parameters to avoid issues like embrittlement. If you're looking for ease of fabrication, 316 is the better option.

Cost: 316 is typically less expensive than 2205. This is because 2205 is a more specialized material and requires more complex manufacturing processes. If budget is a major concern, 316 might be the way to go.To put it simply: for power and extreme weather: 2205 is the winner, but for easy workability and affordability: 316 is king.

Blog Vision Alloys

Making the Right Choice

5. Real-World Scenarios

So, which metal should you choose? It all depends on your specific application. Here are a few real-world scenarios to help you decide:

Marine Applications: If you're building a boat, offshore platform, or anything else that will be exposed to saltwater, 2205 is generally the better choice due to its superior corrosion resistance.

Chemical Processing: In chemical processing plants, where exposure to corrosive chemicals is common, 2205 is often preferred for its resistance to pitting and crevice corrosion. It's also a great choice for tanks and pipelines that need to withstand high pressures.

Food Processing: Both 316 and 2205 are commonly used in food processing equipment. 316 is a good all-around choice, but 2205 might be preferred in applications where higher strength or corrosion resistance is required.

Architectural Applications: For railings, facades, and other architectural elements, 316 is often a good choice due to its aesthetic appeal, ease of fabrication, and good corrosion resistance in most environments.

General Fabrication: For general fabrication projects where strength and corrosion resistance are important but not critical, 316 is often a cost-effective and reliable choice.

304 Vs 316 Stainless Steel Reliance Blog

FAQ

6. Addressing Common Concerns

Let's tackle some of the common questions that often come up when comparing 2205 and 316.

Q: Can I use 316 in saltwater?A: Yes, 316 offers good corrosion resistance in many saltwater environments. However, under prolonged exposure or in areas with high chloride concentrations, 2205 will generally perform better.

Q: Is 2205 magnetic?A: 2205 is slightly magnetic due to its ferrite content, while 316 is generally non-magnetic (although it can become slightly magnetic after cold working).

Q: How do I weld 2205?A: Welding 2205 requires specific techniques and filler metals to maintain its properties. It's important to follow recommended welding procedures and consult with a qualified welding professional.